Wheel size

20/20/26"

Price from

$ 3,999 / € 3,499

AZUB T-TRIS 26 FEATURES

Ergonomic seat

The seat is crucial not only for the comfort when riding a trike, but it will also determine how fast you will be able to corner, whether you and your trike will become true friends and whether you will get the right response from the road that will be running under your wheels. That is why we have devoted so much time to its development as well.

Design is everything

The shape of the tricycle seat is based on the shape of a human back and on the position that the rider adopts. We have spared no expense in getting the bends just right. The seat cushion is long enough to prevent slipping, in the lower back part it copies the proportions of the body, and the curve at the top makes the shoulders and neck bend just right to allow

One size fits all

Our seats compensate for the differences in people’s heights by the mesh cover which can be stretched with straps located at the back. The cover

Setting the tightness

In production, the seat cover is set really tight, though it will loosen a little after several trips. Only then will you experience the feel of its correct side steering, so important during fast cornering. However, the cover should not be loosened too much so that you would slouch, and not too tight sincein some places it could be uncomfortable for your back. You can adjust the tightness of individual sections with the straps at the back of the seat.

Additional padding

If you are looking for maximum comfort and excellent ventilation, then we highly recommend you get additional padding for your seat, the

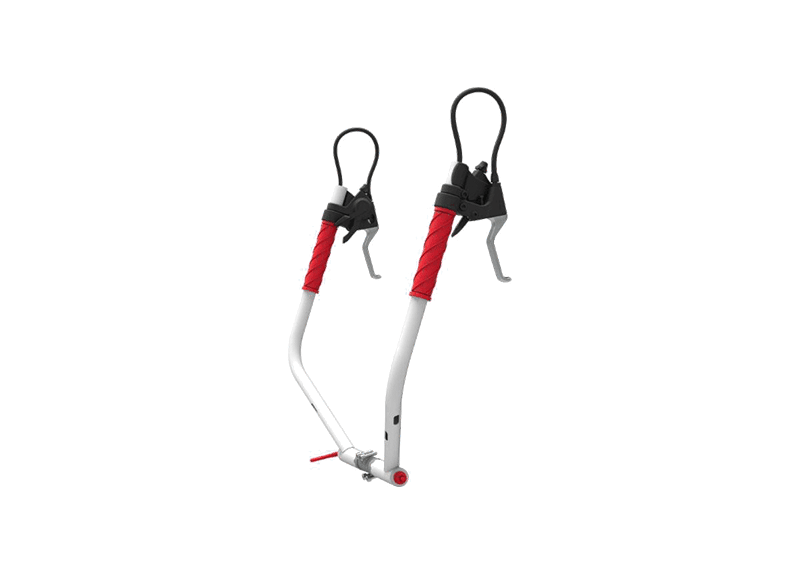

Ergonomics vs. control

If you want to feel nice and comfortable on your bike, it must be both easy to control and ergonomic. However, in some recumbent bikes and trikes you can also find handlebars that don’t really match with the design of common bicycle components. They are tricycle handlebars, or more precisely, the USS. For us, the reverse mounting of brake levers and grip shifters next to the little finger does not constitute a good enough solution. So we use the so called cable loops which solve many complaints that concern the incorrect mounting of grip shifters and brake levers.

Shift and brake simultaneously

A pleasant bonus of the ergonomic mounting of the shifters and brake levers is the ability to brake and change gears at the same time. If you are an experienced cyclist, you are used to adjusting your gears when braking sharply in order to be able to subsequently carry on pedalling in the right cadence. Thanks to the placement of all the elements in our cockpit, you will be able to do this even on your recumbent.

Original shifting

Individual components of modern mountain bikes and road bikes are designed to be fully ergonomic, with an emphasis on easy operation. Using them on recumbent bikes requires special approach and mounting with the help of cable loops and tunnels in handlebars. We can therefore offer you not just the cutting-edge Shimano XT shifters, but also the more economical 8-speed Shimano Alivio. So you can choose to have your favourite shifters that you are used to on your conventional bike fitted onto your dream recumbent, and they will always be placed ergonomically.

Bar end shifters

Bar end shifters, whether from Shimano, SRAM or Microshift, are very popular amongst recumbent riders, particularly on long journeys. We like the overall concept mainly for its simplicity. However, the price and the need to mount the brake levers in reverse is often a problem. We therefore offer these shifters as optional components.

Exceptions

The vast majority of bikes that are created by our experienced mechanics are custom-built according to the wishes of our customers. And although they can choose from the standard combinations of components we offer in our configurator, now and again we do get a special requirement, such as to mount the brake levers only on one side of the handlebars, etc. In these cases, we can mount the grip shifters in reverse, or combine a grip shifter with a classic shift lever. We always consult the special requirements directly with the future rider in order for everybody to be fully satisfied. Us with a job well done, and you with your new machine.

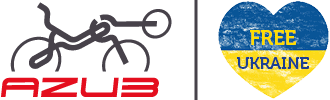

F2F - Fold To Flat

The folding mechanism on our tricycles is positioned in such a way that when you start folding the rear of the frame, the trike slowly “turns” and the rear wheel ends up folded flat. You also remove the seat and, if necessary, also the wheels, so the resulting package is remarkably small.

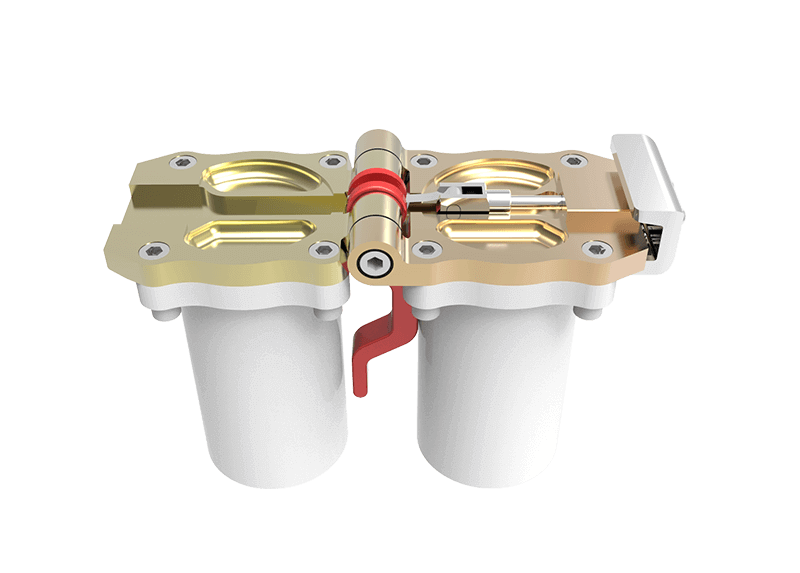

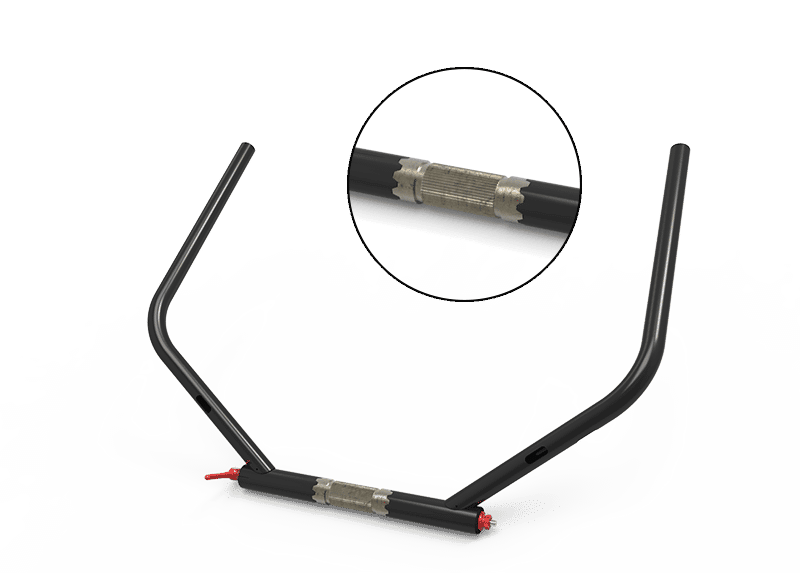

Folding mechanism

In 2015, we introduced a new folding mechanism we are really proud of. We wanted to create a folding tricycle that would be adequately stiff and whose folding mechanism would be smooth and easy to operate. The feedback from hundreds of AZUB riders has confirmed that we have definitely accomplished what we had planned.

XXL lever

The folding mechanism has a large ergonomic lever. By large, we really mean large. It is located on the top of the frame so that it would be easily accessible without having to stick your fingers in hard to reach places. This lever makes folding our

Large diameter

The large diameter of the folding mechanism and the long axle placed in maintenance-free sleeve bearings increase the overall stiffness of the entire folding frame.

Foldable or separable

You can choose whether you want a folding tricycle for easy transport or parking, or a separable one. Our folding mechanism is not integrated into the frame, it is a separate part that is screwed into the frame. It

Adjustability

There is only very little need for adjustments, but now and again, you should adjust the clamping force of the mechanism. It’s easy to do and all you need is an Allen key.

Made with precision

The entire folding mechanism is completely made on a CNC machine. Therefore all the parts fit together perfectly and there is no friction. Precision was a requirement we were not prepared to compromise on at all.

Precision with anodising

Since the machines do so well to produce parts with such high precision, it would be a shame to dip them in

7075

Both halves of the folding mechanism are made of 7075 aluminium which has significantly better properties than any other weldable aluminium.

Perfect connection

In addition, both halves of the folding mechanism have precisely shaped lugs which lock into each other and increase the torsional stiffness of the whole frame. And the stainless steel lock which holds both halves together is machined to a high precision as well.

IGUS bearings

The fluidity with which the two halves of the frame move during the actual folding is truly exceptional, courtesy of the sleeve bearings made by the world renowned manufacturer, IGUS. We just love these small grey pieces of durable plastic. Their functionality is absolutely incredible.

IPS - Ideal Position System

We firmly believe that a bike should adapt to the rider and not the other way round. Therefore, when Aleš designed his first recumbent bike back in 2000, he already tried to make it as adjustable as possible. And today, all our bikes and trikes are like that too. Adjustable features greatly help when learning to ride recumbent. Because when you buy your first recumbent bike, you have no idea if you will prefer sitting more upright or more reclined, you will only be able to decide after many hundreds of miles. With our bikes, adjusting your seating position couldn’t be easier.

Millimetre by millimetre

Two struts with special threads allow you to tilt your seat exactly to the position you want. No matter if you need it set extremely upright or truly reclined. The stability of the whole setup is ensured by two ergonomic locknuts with rubber inserts, and the laser etched markings on each strut make the adjustment very easy.

Smooth adjustment of distance from pedals

The distance between the pedals and the seat can be set not only with the so-called boom, which we usually do according to your height when the bike is built, but also by moving the seat itself. Therefore, when there are two of you taking turns with the bike or when you want to get your friend to try the amazing feeling of reclined riding, you can adjust the seating position on the bike very easily.

Fantastic range of positions for handlebars

The handlebars can be set to an extremely wide range of positions. The way they are set in the stem is the same like in a classic bike. In recumbents with ASS, it is also possible to set the tilt of the stem and the distance of the handlebars from the body, in short, to create the most comfortable seating ever.

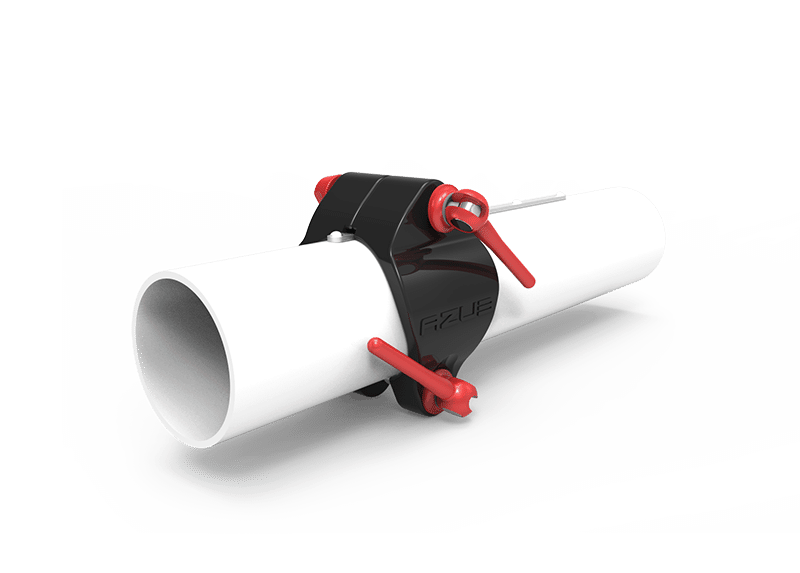

Sliding sleeve for the seat

The sliding sleeve is made of glass fibre reinforced plastic. You can set your seat with millimetre precision and it will only take a few seconds as everything is controlled by two red anodized quick releases. Easy, fast, functional.

Smooth adjustment of the seat

Ever since we started back in 2000, we have always thought that a bike should adapt to the rider and not the other way round. That’s why we used an adjustable seat for our first bike, in which both the angle and the pedal distance were adjustable. With each further development stage, we introduced a more accurate adjustment, until 2013, when we reached a stage of adjusting without positions. This concept is based on a sliding sleeve, which we produce in a straight version for our tricycles and some bicycles, as well as in a curved version for recumbents.

Reinforced with glass fibre

The sleeve is made of durable, glass fibre reinforced plastic which we opted for in order to prevent scratching of the paint even during frequent use.

Perfect fit

It is extremely important for the seat to be secure whilst riding, which is why there are two small hard-anodised aluminium parts attached to the lower part of the seat. They fit onto a three-part stainless steel insert that is fitted within the sleeve itself. When you tighten the quick release, everything slots together nice and tight.

Speed and simplicity

Adjusting the seat is very easy. The upper quick release is used to secure the seat and when you release the lower one, the grip around the frame loosens and the seat can be moved. If you are a heavy rider, the lower quick release must be tightened really firmly.

Join the worldwide group of AZUB fans

Get the latest stories, be inspired by our amazing builds and get some inside view.

You are close to join the fan group. Just see your inbox and confirm your e-mail address.